|

|

|

Regulatory

Codes & Regulations

IMPORTANT: Actual codes vary by city. Check with the Authorities Having Jurisdiction (AHJ) for all applicable code requirements.

OSHA Quick Links

OSHA Injury Tracking Application

Electronic Submission of Injury and Illness Records to OSHA

Containment Requirements

Building and fire codes are developed by associations for adoption by federal, state, and local authorities having jurisdiction. The local municipalities often make amendments or changes to the model codes during the adoption process and, in some cases, choose not to update to newer model codes and keep the older codes in place for enforcement. Codes are REGULATORY and are typically enforced by government officials.

Because code adoption varies by each municipality, due diligence must be exercised to confirm compliance requirements. Failure to understand code requirements prior to installation could result in added costs, lost labor and project delays. For more information on codes, contact EnviroGuard.

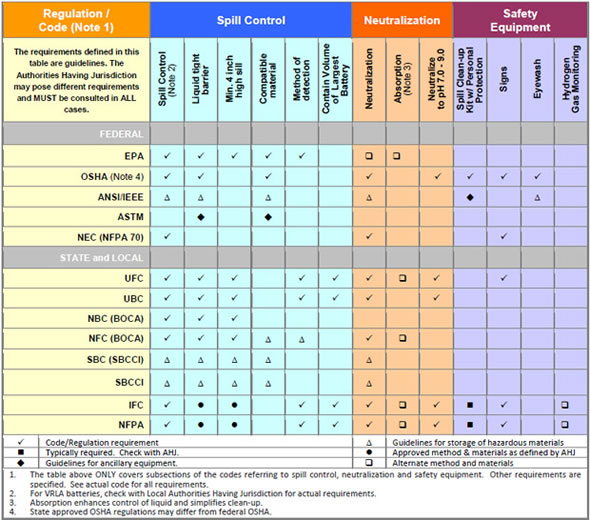

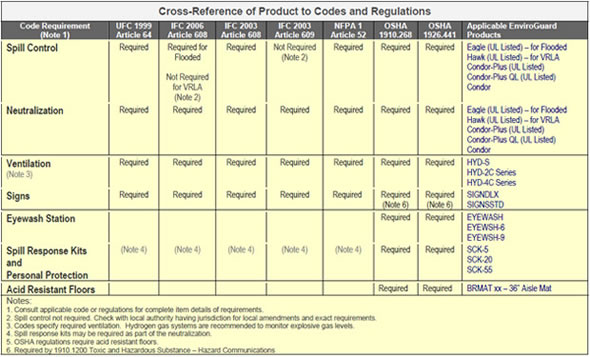

Code/Regulation Requirement Table .....

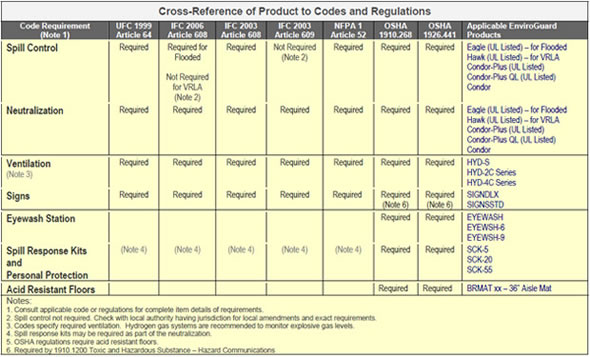

Product Cross-Reference to Code and Regulation .....

IMPORTANT: The table below lists the common model codes ONLY. Actual Codes vary by city. CHECK WITH THE AUTHORITY HAVING JURISDICTION FOR ALL APPLICABLE CODE REQUIREMENTS.

Code and Regulation Summaries

The following summaries are a partial list of the codes and regulations associated with battery room spill containment and safety equipment for compliance. Check with Federal, State, and local authorities having jurisdiction for complete compliance requirements.

Code, Regulatory, and Standards Authorities .....

- IFC (International Fire Code)

2000 Section 608, 2003 Section 608 (Flooded) & Section 609 (VRLA), 2006 & 2009 Section 608

- NFPA (National Fire Prevention Authority)

NFPA 1 Article 52, NFPA 70 (NEC) National Electrical Code

- UFC (Uniform Fire Code)

Article 64 and Section 80.304,314

- UBC (Uniform Building Code)

Section 304.8

- BOCA (Building Officials and Code Administrators)

NBC (National Building Code) - Section 417,

- NFC (National Fire Code)

Section F-2315, F-2802

- SBCCI (Southern Building Code Congress International)

- SBC (Standard Building Code)

Section 407, Standard Fire Prevention Code, Section 2203

- OSHA (Occupational Safety and Health Administration)

29 CFR 1926.441, 29 CFR 1910.268, 29 CFR 1910.151

- ANSI (American National Standards Institute)

- IEEE (Institute of Electrical and Electronic Engineers)

Standard 1187-1996, 484-1996

- ASTM (American Society of Testing and Materials)

- EPA (Environmental Protection Agency)

Title 40 Code of Federal Regulations – 40 CFR 264.175

Uniform Fire Code (UFC), 1999 .....

ARTICLE 64 Stationary Lead-Acid Battery Systems

6401 Scope. The scope of the article applies to all battery types, including Valve Regulated Lead Acid (VRLA) and gel cell batteries. The definition of "lead-acid battery" includes all "electrochemical cells interconnected to supply a nominal voltage of DC power…" The revision broadens the scope of the article to regulate battery systems over 50 gallons (189.3 L) aggregate capacity reducing the prior 100 gallons(378.5 L) minimum that previously existed. This was done to ensure Article 64, rather than Article 50, applies to these systems per the original intent.

The electrolyte in stationary lead acid battery systems (SLABS) contain sulfuric acid, which is classified as toxic when in concentrations over 12.5 percent (IFCI's Hazardous Materials Classification Guide). Previously, Article 80 is applicable to battery systems with an electrolyte capacity between 50 gallons (189.3L) and 100 gallons (378.5L) in occupancies unprotected by sprinklers. The adoption of Article 64 Supplement 1999 more specifically addresses hazards related to battery systems and is now applicable to all systems over 50 gallons(189.3 L). If individual lead-acid batteries with liquid capacity exceeding 20 gallons, each shall also comply with Article 80.

6402 Definitions. For definitions of LEAD-ACID BATTERY and STATIONARY LEADACID BATTERY SYSTEM, see Article 2.

6403 Permits.

6403.1 General. For a permit to install or operate battery systems with stationary lead-acid batteries, see Section 105.8, permit b.1.

6403.2 Design Submittals. Prior to installation, plans shall be submitted and approved.

6404 Installation and Maintenance.

6404.1 General. Installation and maintenance of battery systems shall be in accordance with nationally recognized standards. See Section 9003, Standards a.2.10 and a.2.11, and Section 6404.

6404.2 Safety Venting. Batteries shall be provided with safety venting caps.

6404.3 Occupancy Separation. In other than A,E,I and R Occupancies, battery systems shall be located in a room separated from other portions of the building by a minimum one-hour resistive occupancy separation. In A,E,I and R Occupancies, battery systems shall be located in a room separated from other portions of the building by a two-hour-fire-resistive occupancy separation.

6404.4 Spill Control. Each rack of batteries or group of racks shall be provided with a liquid tight 4-inch spill-control barrier which extends at least 1inch beyond the battery rack in all directions.

6404.5 Neutralization. An approved method to neutralize spilled electrolyte shall be provided. The method shall be capable of neutralizing a spill from the largest lead-acid battery to a pH between 7.0 - 9.0.

6404.6 Ventilation. Ventilation shall be provided in accordance with the Mechanical Code and the following:

1. The ventilation system shall be designed to limit the maximum concentration of hydrogen to 1.0% of the total volume of the room in accordance with nationally recognized standards, or

2. Continuous ventilation shall be provided at a rate of not less than 1 cubic foot per minute, per square foot (.51L/s per m2) of floor area of the room.

6404.7 Signs. Doors into rooms or buildings containing stationary lead-acid battery systems shall be provided with approved signs. The signs shall state that the room contains lead-acid battery systems, that the battery room contains energized electrical circuits and that the battery electrolyte solutions are corrosive liquids.

6404.8 Seismic Protection. Battery systems shall be seismically braced in accordance with the Building Code.

6504.9 Smoke Detection. An approved automatic smoke detection system shall be installed in such areas and supervised by an approved central proprietary or remote station service or local alarm which will give an audible signal at a constantly attended location.

International Fire Code 608-2003 - Stationary Lead-Acid Battery Systems .....

Chapter 6, Building Services and Systems

SECTION 608- STATIONARY LEAD-ACID BATTERY SYSTEMS

608.1 Scope. Stationary lead-acid battery systems using vented (flooded) lead-acid batteries having an electrolyte capacity of more than 50 gallons (189 L) used for facility standby power, emergency power, or uninterrupted power supplies (UPS) shall comply with this section. Valve-regulated lead-acid batteries are not subject to the requirements of this section, but shall comply with Section 609.

608.2 Safety Venting. Batteries shall be provided with safety venting caps.

608.4 Spill Control and Neutralization. An approved method and materials for the control and neutralization of a spill of electrolyte shall be provided. The method and materials shall be capable of controlling and neutralizing a spill from the largest lead-acid battery to a pH between 7.0 and 9.0.

608.6 Signs. Doors into rooms or buildings containing stationary lead-acid battery systems shall be provided with approved signs. The signs shall state that the room contains lead-acid battery systems, that the battery room contains energized electrical circuits, and that the battery electrolyte solutions are corrosive liquids.

SECTION 609- VALVE-REGULATED LEAD-ACID (VRLA) BATTERY SYSTEMS

609.1 Scope. Valve-regulated lead-acid (VRLA) battery systems having an electrolyte capacity of more than 50 gallons (189 L) used for facility standby power, emergency power or uninterrupted power supplies (UPS) shall comply with this section.

609.2 Safety Vents. VRLA batteries shall be equipped with self-resealing, flame-arresting, safety vents.

609.5 Neutralization. An approved manual method and materials for the neutralization of a release of electrolyte shall be provided. The method and materials shall be capable of controlling and neutralizing a release of 3 percent of the capacity of the largest VRLA cell or block in the room to a pH between 7.0 and 9.0.

International Fire Code 608-2006 - Stationary Storage Battery Systems .....

Code Agency: ICC (International Code Council)

Article Number: IFC 608 (International Fire Code)

Model Date: 2006

Amendments: See state, city& local amendments

Note: Confirm all requirements with local authority having jurisdiction.

608.1 Scope. Stationary storage battery systems having an electrolyte capacity of more than 50 gallons (189 L) for flooded lead acid, nickel cadmium (Ni-Cd) and valve-regulated lead acid (VRLA), or 1,000 pounds (454 kg) for lithium-ion, used for facility standby power, emergency power or uninterrupted power supplies, shall comply with this section and Table 608.1.

608.2 Safety caps. Safety caps for stationary storage battery systems shall comply with Sections 608.2.1 and 608.2.2.

608.2.1 Nonrecombinant batteries. Vented lead acid, nickel-cadmium or other types of nonrecombinant batteries shall be provided with safety venting caps.

608.2.2 Recombinant batteries. VRLA batteries shall be equipped with self-resealing flame-arresting safety vents.

608.3 Thermal runaway. VRLA battery systems shall be provided with a listed device or other approved method to preclude, detect and control thermal runaway.

608.4 Room design and construction. Enclosure of stationary battery systems shall comply with the International Building Code. Battery systems shall be allowed to be in the same room with the equipment they support.

608.4.1 Separate rooms. When stationary batteries are installed in a separate equipment room accessible only to authorized personnel, they shall be permitted to be installed on an open rack for ease of maintenance.

608.4.2 Occupied work centers. When a system of VRLA, lithium-ion, or other type of sealed, non-venting batteries is situated in an occupied work center, it shall be allowed to be housed in a noncombustible cabinet or other enclosure to prevent access by unauthorized personnel.

608.4.3 Cabinets. When stationary batteries are contained in cabinets in occupied work centers, the cabinet enclosures shall be located within 10 feet (3048 mm) of the equipment that they support.

608.5 Spill control and neutralization. An approved method and materials for the control and neutralization of a spill of electrolyte shall be provided in areas containing lead-acid, nickel-cadmium or other types of batteries with free-flowing liquid electrolyte. For purposes of this paragraph, a "spill" is defined as any unintentional release of electrolyte. Exception: VRLA, lithium-ion or other types of sealed batteries with immobilized electrolyte shall not require spill control.

608.5.1 Nonrecombinant battery neutralization. For battery systems containing lead-acid, nickel-cadmium or other types of batteries with free-flowing electrolyte, the method and materials shall be capable of neutralizing a spill from the largest lead acid battery to a pH between 7.0 and 9.0.

608.5.2 Recombinant battery neutralization. For VRLA or other types of sealed batteries with immobilized electrolyte, the method and material shall be capable of neutralizing a spill of 3 percent of the capacity of the largest VRLA cell or block in the room to a pH between 7.0 and 9.0. Exception: Lithium-ion batteries shall not require neutralization.

608.6 Ventilation. Ventilation of stationary storage battery systems shall comply with Sections 608.6.1 and 608.6.2.

608.6.1 Room ventilation. Ventilation shall be provided in accordance with the International Mechanical Code and the following:

1. For flooded lead acid, flooded nickel-cadmium, and VRLA batteries, the ventilation system shall be designed to limit the maximum concentration of hydrogen to 1 percent of the total volume of the room; or

2. Continuous ventilation shall be provided at a rate of not less than 1 cubic foot per minute per square foot [1 ft3/min/ft2 or 0.0051 m3/(s m2)] of floor area of the room.

Exception: Lithium-ion batteries shall not require ventilation.

608.6.2 Cabinet ventilation. When VRLA batteries are installed inside a cabinet, the cabinet shall be approved for use in occupied spaces and shall be mechanically or naturally vented by one of the following methods:

1. The cabinet ventilation shall limit the maximum concentration of hydrogen to 1 percent of the total volume of the cabinet during the worst-case event of simultaneous "boost" charging of all the batteries in the cabinet; or

2. When calculations are not available to substantiate the ventilation rate, continuous ventilation shall be provided at a rate of not less than 1 cubic foot per minute per square foot [1 ft3/min/ft2 or 0.0051 m3/(s * m2)] of floor area covered by the cabinet. The room in which the cabinet is installed shall also be ventilated as required in Section 608.6.1.

608.7 Signage. Signs shall comply with Sections 608.7.1 and 608.7.2.

608.7.1 Equipment room and building signage. Doors into electrical equipment rooms or buildings containing stationary battery systems shall be provided with approved signs. The signs shall state that:

1. The room contains energized battery systems.

2. The room contains energized electrical circuits.

3. The battery electrolyte solutions, where present, are corrosive liquids

608.7.2 Cabinet signage. Cabinets shall have exterior labels that identify the manufacturer and model number of the system and electrical rating (voltage and current) of the contained battery system. There shall be signs within the cabinet that indicate the relevant electrical, chemical and fire hazards.

608.8 Seismic protection. The battery systems shall be seismically braced in accordance with the International Building Code.

608.9 Smoke detection. An approved automatic smoke detection system shall be installed in accordance with Section 907.2 in rooms containing stationary battery systems.

NFPA 1- Uniform Fire Code, 2006 Edition .....

Chapter 52 Stationary Lead–Acid Battery Systems

52.1 General. Stationary lead-acid battery systems having an electrolyte capacity of more than 100 gal (378.5 L) in sprinklered buildings or 50 gal (189.3 L) in unsprinklered buildings used for facility standby power, emergency power, or uninterrupted power supplies shall be in accordance with Chapter 52.

52.3 Safety Features.

52.3.1 Safety Venting. Batteries shall be provided with safety venting caps. 1–216 UNIFORM FIRE CODE 2006 Edition

52.3.4 Spill Control.

52.3.4.1 Rooms, buildings, or areas containing free-flowing liquid electrolyte in individual vessels having a capacity of more than 55 gal (208 L) or multiple vessels having an aggregate capacity exceeding 1000 gal (3785 L) shall be provided with spill control to prevent the flow of liquids to adjoining areas.

52.3.4.2* An approved method and materials for the control of a spill of electrolyte shall be provided. The method shall be capable of controlling a spill from the single largest vessel.

52.3.5 Neutralization.

52.3.5.1 An approved method to neutralize spilled electrolyte shall be provided.

52.3.5.2 The method shall be capable of neutralizing a spill from the largest lead–acid battery to a pH between 7.0 and 9.0.

52.3.8 Signs.

52.3.8.1 Doors or accesses into rooms, buildings, or areas containing stationary lead–acid battery systems shall be provided with approved signs.

52.3.8.2 The signs shall state that the room contains lead–acid battery systems, that the battery room contains energized electrical circuits, and that the battery electrolyte solutions are corrosive liquids.

52.3.8.3 Battery cabinets shall be provided with exterior labels that identify the manufacturer and model number of the system and electrical rating (voltage and current) of the contained battery system. Within the cabinet, signs shall be provided to indicate the relevant electrical, chemical, and fire hazard.

*A.52.3.4.2 Methods of achieving this protection can include, but are not limited to, the following:

(1) Liquid tight sloped or recessed floors in indoor locations or similar areas in outdoor locations

(2) Liquid tight floors in indoor locations or similar areas in outdoor locations provided with liquid tight raised or recessed sills or dikes

(3) Sumps and collection systems

Chapter 3 – Definitions

3.3.21 Battery (Lead-Acid).

3.3.21.1* Valve-Regulated (VRLA). A lead-acid battery consisting of sealed cells furnished with a valve that opens to vent the battery whenever the internal pressure of the battery exceeds the ambient pressure by a set amount.

3.3.21.2* Vented (Flooded). A lead-acid battery consisting of cells that have electrodes immersed in liquid electrolyte.

3.3.22 Battery System (Lead-Acid). A system that consists of these interconnected subsystems: (1) lead-acid batteries; (2) battery chargers; and (3) a collection of rectifiers, inverters, converters, and associated electrical equipment as required for a particular application.

NFPA 76 Standard for the Fire Protection of Telecommunication.....

Industries 2005 Edition

Chapter 6 Prescriptive-Based Approaches

6-10 Power Areas

6.10.8* Special Hazards. Stationary lead acid battery areas shall comply with NFPA 1.

*A.6.10.8 Where spill containment systems are used, they should be evaluated to address flammability. The assessment should take into consideration the ignition resistance and propensity to propagate fire of the product assembly with consideration of the contribution of the components (outer encasement, absorbent materials, liners, or other components). In a previous loss investigation it was determined that the fire originated in the battery rack and the flame spread was promoted by the flammability of the fabric covering on the acid spill containment bags. ASTM E648 can be used to determine the critical flux for propagation of flames along spill containment systems when installed on a floor. The most stringent requirement of model building or fire codes is Class 1, which has critical flux of 0.45 W/cm2.

The BOCA® National Building code / 1999 .....

Chapter 3 Use or Occupancy

Section 317 – High Hazard Use Groups

307.8 Exceptions:

The following shall not be classified in Use Group H, but shall be classified in the use group which they most nearly resemble. Hazardous materials in any quantity shall conform to the requirements of this code, including Section 417.0, and the fire prevention code listed in Chapter 35.

307.8.13. Stationary batteries utilized for facility emergency power, uninterrupted power supply or telecommunication facilities provided that the batteries are provided with safety venting caps and ventilation is provided in accordance with the mechanical code listed in Chapter 35.

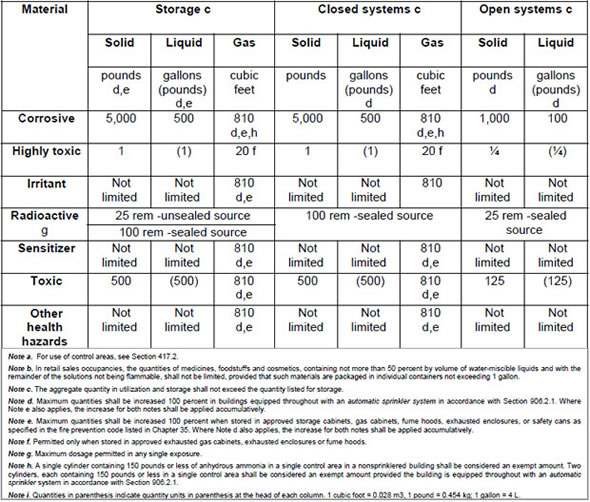

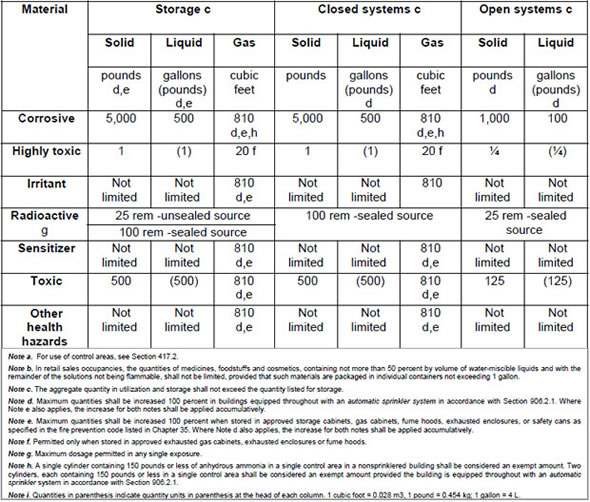

Table 307.8(2)

EXEMPT AMOUNTS OF HAZARDOUS MATERIALS, LIQUIDS, AND CHEMICALS PRESENTING A HEALTH HAZARD(USE GROUP H-4) MAXIMUM QUANITITIES PER CONTROL AREA a, b, i

Chapter 4 Special Use and Occupancy

Section 417 – Hazardous Materials

417.1 General:

The provisions of this section shall apply to all buildings and structures occupied for the manufacturing, processing, dispensing, use or storage of hazardous materials. All buildings and structures with an occupancy in Use Group H shall also comply with the applicable provisions of Section 418.0 and the fire prevention code listed in Chapter 35.

417.4 Hazardous material systems:

Systems involving hazardous materials shall be suitable for the intended application and shall be designed by persons competent in such design. Controls shall be designed to prevent materials from entering or leaving process or reaction systems at other than the intended time, rate or path. Automatic controls, where provided, shall be designed to be fail safe.

417.5 Inside storage, dispensing and utilization:

The inside storage, dispensing and utilization of hazardous materials in excess of the exempt amounts of Tables 307.8(1) and 307.8(2) shall be in accordance with Sections 417.5.1 through 417.5.5 and the fire prevention code listed in Chapter 35 .

417.5.5 Spill control, drainage and containment:

Rooms, buildings or areas occupied for the storage of solid and liquid hazardous materials shall be provided with a means to control spillage and to contain or drain off spillage and fire protection water discharged in the storage area where required in Section 418.0 and the fire prevention code listed in Chapter 35.

SECTION 418.0 - USE GROUPS H-1, H-2, H-3 AND H-4

418.3.2.5 Leakage containment:

A liquid-tight containment area compatible with the stored liquid shall be provided to retain 110 percent of the entire capacity of all the storage liquid in the event of a leak in a tank plus the capacity of the automatic fire suppression system activated for a period of 30 minutes. The storage tanks and the leakage containment area shall be provided with an approved method to drain manually the flammable or combustible liquid.

Exception:

Rooms where only double- wall storage tanks conforming to Section 418.3.2.3 are used to store Class I, II and IIIA flammable and combustible liquids shall not be required to have a leakage containment area.

CHAPTER 23 - HAZARDOUS MATERIALS

SECTION F-2315.0 - SPILL CONTROL, DRAINAGE AND CONTAINMENT

F-2315.1 Where required:

Where required in Chapters 24 through 43, rooms, structures or areas utilized for the storage of solid and liquid hazardous materials exceeding the exempt amounts shall be provided with a means to control spillage and contain or drain off spillage and fire protection water discharged in the storage area in accordance with this section.

F-2315.2 Spill control:

Floors shall be liquid tight and recessed a minimum of 4 inches (102 mm) or shall be provided with a liquid tight 4-inch (102 mm) raised sill to prevent the flow of liquids to adjoining areas. Liquid tight sills, where provided, shall be omitted at door openings protected with the installation of an open grate trench connecting to the room drainage system.

CHAPTER 28 - LIQUID AND SOLID CORROSIVE MATERIALS

SECTION F-2801.0 - GENERAL

F-2801.1 Scope:

This chapter shall apply to the storage and use of solid and liquid corrosive materials in addition to the requirements of Chapter 23, except that this chapter shall not apply to mercantile display and storage areas for nonflammable solid and nonflammable or non combustible liquid corrosive materials complying with Section F-2307.1.

F-2801.2 Approval required:

Approval shall be required for the storage and use of corrosive materials exceeding 1,000 pounds (454 kg) of solids or 110 gallons (416 L) of liquids.

F-2801.3 Use group classification:

Occupancies containing corrosive materials exceeding the exempt amounts per control area indicated in Table F-2801.3 shall be classified as Use Group H-4.

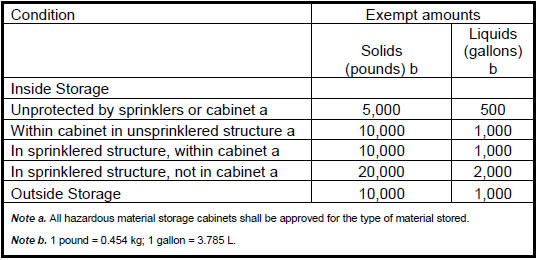

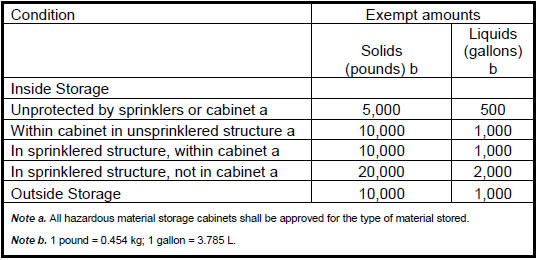

Table F-2801.3

LIQUIDS AND SOLID CORROSIVE MATERIALS EXEMPT AMOUNT FOR STORAGE

(MAXIMUM QUANTITIES PER CONTROL AREA)

SECTION F-2802.0 - RETROACTIVE REQUIREMENTS

F-2802.1 General:

The provisions of this section shall apply to all new and existing structures occupied for the storage of corrosive materials exceeding the exempt amounts per control area, unless otherwise specified.

F-2802.2 Inside storage:

Inside storage of corrosive materials shall comply with Sections F-2802.2.1 through F-2802.2.3.

F-2802.2.1 Spill control, drainage and containment:

Spill control, drainage, and containment shall be provided for the storage of corrosive liquids in accordance with Section F-2315.1 in other than existing structures occupied for the inside storage of corrosive liquids.

OSHA 1926.441 Batteries and battery charging

1926.441(a) - General requirements

1926.441(a)(1) Batteries of the unsealed type shall be located in enclosures with outside vents or in well ventilated rooms and shall be arranged so as to prevent the escape of fumes, gases, or electrolyte spray into other areas.

1926.441(a)(3) Racks and trays shall be substantial and shall be treated to make them resistant to the electrolyte.

1926.441(a)(4) Floors shall be of acid resistant construction unless protected from acid accumulations.

1926.441(a)(5) Face shields, aprons, and rubber gloves shall be provided for workers handling acids or batteries.

1926.441(a)(6) Facilities for quick drenching of the eyes and body shall be provided within 25 feet (7.62 m) of battery handling areas.

1926.441(a)(7) Facilities shall be provided for flushing and neutralizing spilled electrolyte and for fire protection.

OSHA 1910.268 Telecommunications

1910.268(b)(2) Battery handling.

1910.268(b)(2)(i)

Eye protection devices which provide side as well as frontal eye protection for employees shall be provided when measuring storage battery specific gravity or handling electrolyte and the employer shall ensure that such devices are used by the employees. The employer shall also ensure that acid resistant gloves and aprons shall be worn for protection against spattering. Facilities for quick drenching or flushing of the eyes and body shall be provided unless the storage batteries are of the enclosed type and equipped with explosion proof vents, in which case sealed water rinse or neutralizing packs may be substituted for the quick drenching or flushing facilities. Employees assigned to work with storage batteries shall be instructed in emergency procedures such as dealing with accidental acid spills.

1910.268(b)(2)(ii)

Electrolyte (acid or base, and distilled water) for battery cells shall be mixed in a well ventilated room. Acid or base shall be poured gradually, while stirring, into the water. Water shall never be poured into concentrated (greater than 75 percent) acid solutions. Electrolyte shall never be placed in metal containers nor stirred with metal objects.

1910.268(b)(2)(iii)

When taking specific gravity readings, the open end of the hydrometer shall be covered with an acid resistant material while moving it from cell to cell to avoid splashing or throwing the electrolyte.

1910.268(b)(3)

Employers must provide employees with readily accessible, adequate, and appropriate first aid supplies. A non-mandatory example of appropriate supplies is listed in Appendix A to 29 CFR 1910.151.

Application briefs

Taking the Confusion out of Battery Room Signage .....

Signage for battery rooms is an important requirement to satisfy fire codes, occupational safety regulations, "Right to Know" Act and Authorities Having Jurisdiction. This brief explores the required signage for standby power battery rooms, cabinets and systems.

Prevent Explosive Hazards from Back up Batteries Emitting Hydrogen Gas .....

The need for gas monitoring occurs while lead acid backup batteries are being charged. This charging process generates hydrogen gas which is emitted into the battery storage room can build up and potentially explode if ignited. This paper explores the use of hydrogen gas monitoring to enable early warning and mitigation.

Case Studies

Containment or Compliance? Dispelling the myths .....

Spill containment is a requirement of federal, state and local fire and hazardous material codes, regulations, ordinances and guidelines. While these vary by municipality, recent fire codes for stand-by battery systems call for approved methods and materials for acid spill control and neutralization. When viewed as a commodity, spill containment materials appear to have similar traits and features.

Tools & Checklists

Spill Containment Sizing and Configuration Worksheet.....

This worksheet is designed to facilitate the sizing and configuring of spill containment systems.

Compliance Checklist .....

Battery room compliance checklist provides complete battery room checklist for compliance requirements including Regulatory references.

Site Assessment .....

Battery room site assessment checklist provides complete battery room checklist for spill containment and safety equipment.

|